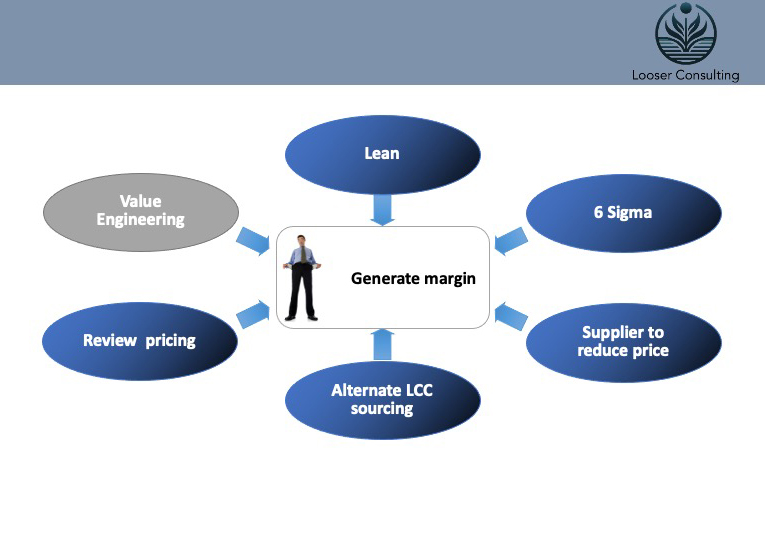

In today’s business landscape, organizations have access to a wide range of cost reduction strategies. Some of the most well-known methods include Lean, Six Sigma, Supplier Price Reduction, Alternative LCC Sourcing, Review Pricing, and Value Engineering. Each approach offers its own advantages – but when it comes to comprehensive, sustainable cost reduction, Value Engineering stands out.

Lean

Lean focuses on minimizing waste and maximizing efficiency. By streamlining processes, companies can achieve significant cost savings. However, Lean typically works within existing processes and has a limited impact on the product development phase.

Six Sigma

Six Sigma improves process quality by reducing errors and deviations, leading to lower costs and improved quality. However, its implementation requires significant training and resources, which can sometimes outweigh the cost savings.

Supplier Price Reduction

Negotiating with suppliers to lower prices can bring short-term savings, but it heavily depends on market conditions and often affects only the direct material costs without addressing broader systemic inefficiencies.

Alternative LCC Sourcing

Low-Cost Country (LCC) sourcing shifts procurement to countries with lower labor and production costs. While this can greatly reduce expenses, it also comes with risks regarding quality control and supply chain stability.

Review Pricing

Regularly reviewing pricing structures can help businesses remain competitive and adjust to market conditions. However, this is more of a short-term strategy, addressing the symptoms of cost issues rather than their root causes.

Why Value Engineering is the Best Choice

Value Engineering sets itself apart from these methods because it focuses not just on a single phase of the product lifecycle, but takes a holistic approach. It aims to maximize the value of a product by eliminating unnecessary costs without compromising quality or functionality. Value Engineering drives innovation by constantly questioning every aspect of a product or process to find better, more efficient solutions. It’s about creating true value, not just cutting costs in the short term.

While the other approaches have their merits, Value Engineering is the key to long-term cost reduction and sustainable competitive advantage. By focusing on innovation and value creation, Value Engineering provides the best foundation for companies looking to invest in their future success.

No responses yet